Belts

Discs

Other abrasives

Tapes & Sealants

Focus products

About us

Mr Daniël van der Poort founded Danpoort in 1932. As time passed, the business expanded in size to become a major industrial supplier of sanding, grinding and polishing materials.

Timesavers international can trace its origins back as far as 1939 when Arie van der Linden started a repair shop for woodworking machinery in Rotterdam in The Netherlands. By 1953 the company had gone on to also specializing in stroke sander and drum sander machinery, and by 1963 wide-belt sanders have been added to the array of abrasive equipment being produced. From the 1970s the company started working not only with wood but also with metals, aluminium, carbon and stainless steels.

Twenty years later saw the start of Timesavers International BV in 1996 which took care of all Timesavers activities in the world with the exception of the north American continent. The company had become the world market leader in wide-belt sanding and grinding machines for wood and metal applications.

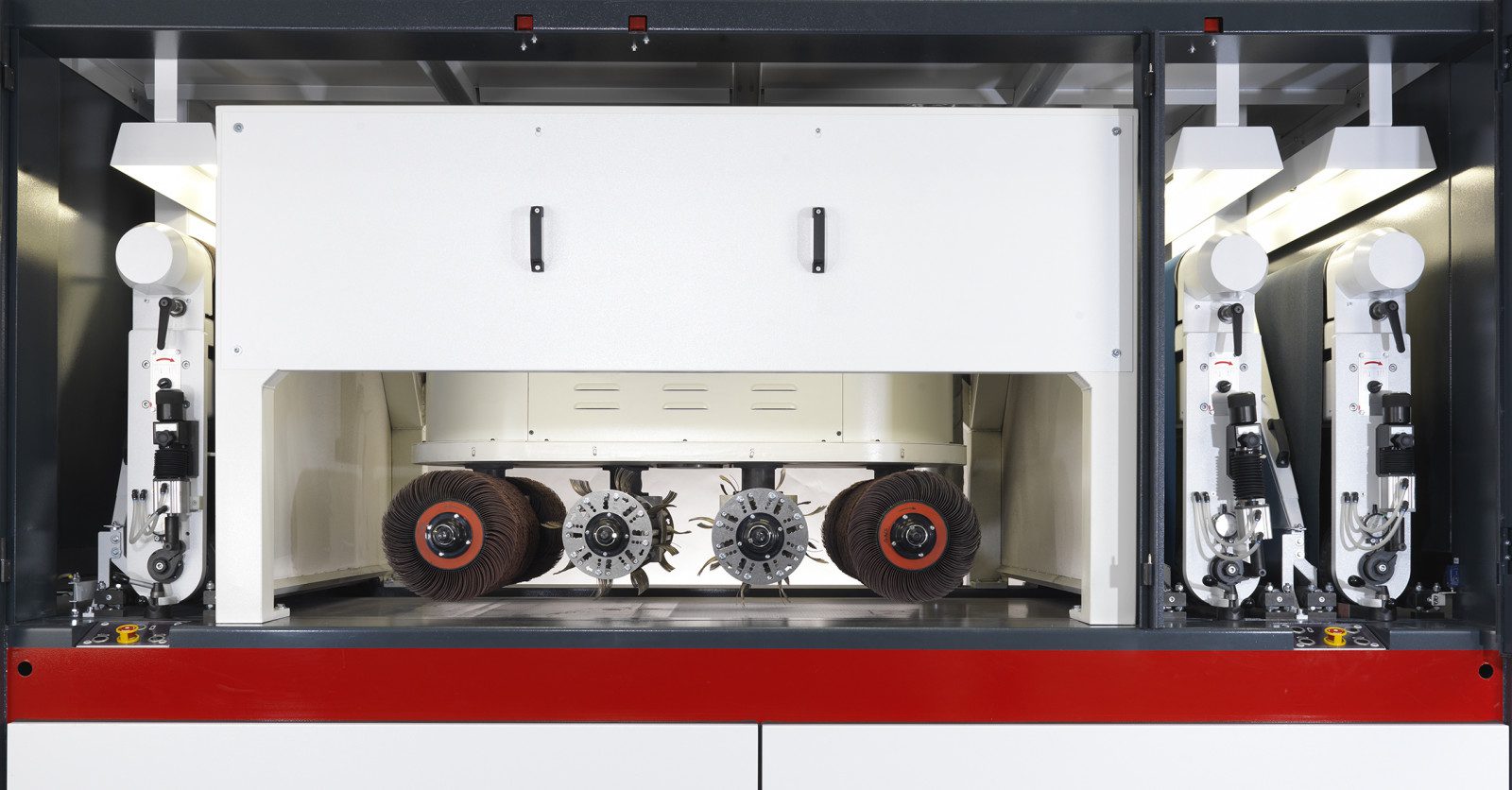

Today the company specializes in a broad selection machines for grinding, finishing, precision grinding, and deburring metal plates. In some cases this involves removing as little as a few microns from the surface of the material with great accuracy. In other cases, it may mean taking away anything up to several millimeters from a plate all at once. Nowadays the company operates from three facilities – one in Minneapolis in the USA where the majority of the company’s woodworking machines are still constructed, Goes where the medium duty, heavy duty and special metal machines are made, and China from where the Asian market is served with the machines.

Since 2022 Danpoort International Abrasives and Timesavers are working closely in the worldwide market to support customers with the right product on wide and segmented grinding and finishing belts. Danpoort has become a specialist in producing (segmented) wide belt grinding solutions. Danpoort can manufacture segmented wide belts up to a maximum width of 3450 mm. Based on a wide portfolio of qualities we are able to offer our customers always a solution for their specific application for either grinding or finishing.

Based on a wide portfolio of qualities we are able to offer our customers always a solution for their specific application for either grinding or finishing.

With our own modern production facility, we can quickly provide you with a customized solution and are happy to think along with you in optimizing your current grinding processes. We have options from standard to high-end grinding and deburring solutions and offer a very wide range of various qualities and brands. Danpoort also offers the ability to stock specific sanding belts for our customers so that we can supply them directly from stock (on demand). This guarantees just-in-time delivery and ensures security for their production processes.